Precision CNC machining services for marine engine components, propellers, hull structures, deck equipment, and propulsion systems with unmatched quality and reliability.

Advanced CNC manufacturing capabilities combined with deep marine industry expertise delivering precision components for critical maritime applications.

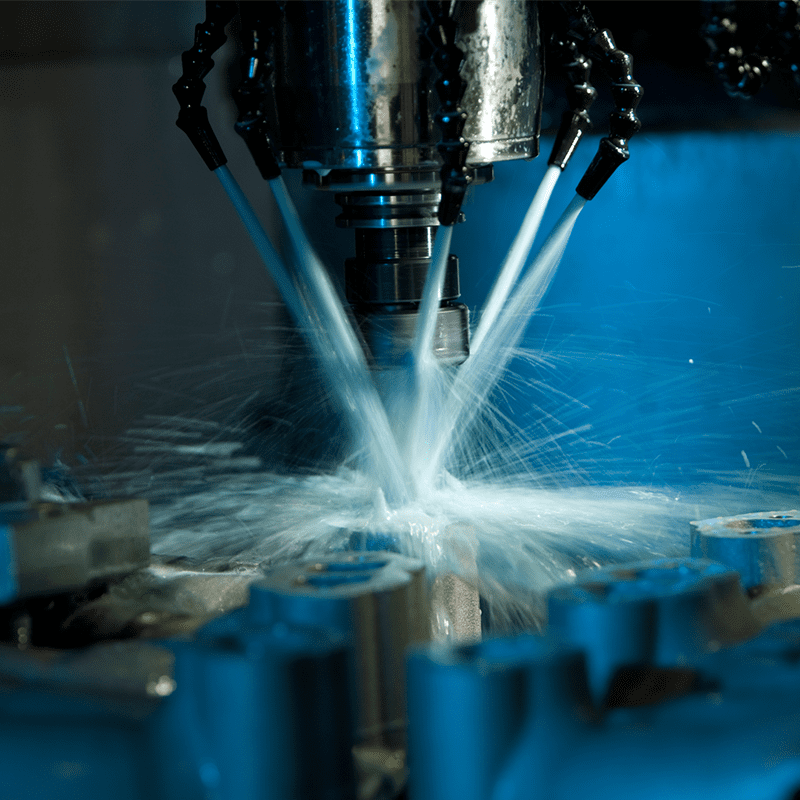

Tolerances as tight as ±0.001″ with surface finishes down to Ra 0.2μm for critical marine applications.

ISO 9001:2015 certified with specialized marine material expertise and corrosion resistance standards.

Rapid prototyping and production capabilities with emergency repair services for critical vessel downtime.

25+ years serving shipyards, naval architects, and marine equipment manufacturers worldwide.

State-of-the-art machining centers and fabrication equipment specifically configured for marine industry requirements.

Complex geometry machining for propellers, impellers, and turbine components with continuous 5-axis interpolation.

Horizontal boring mills up to 200″ capacity for large engine blocks, hull components, and deck structures.

Optimized for aluminum marine alloys and stainless steel with advanced tool path strategies.

Turn-mill centers for complete shaft and propeller hub machining in single setups.

Certified marine welders for aluminum, stainless steel, and specialty alloys with full penetration testing.

Anodizing, passivation, and specialized marine coatings for enhanced corrosion resistance.

CMM measurement, NDT testing, and dimensional verification with full traceability documentation.

24/7 emergency machining services for critical vessel repairs and component replacement.

Comprehensive CNC manufacturing solutions for all critical marine and shipbuilding components. Precision machining of critical engine components including cylinder heads, engine blocks, crankshafts, connecting rods, and cooling system components. Fabrication and machining of hull structural components, frames, bulkheads, and specialized fittings for vessel construction and repair. Advanced 5-axis CNC machining of propeller blades, hubs, shafts, and complete propulsion system components with optimal hydrodynamic profiles. Manufacturing of deck machinery, winches, windlasses, davits, and specialized marine equipment for vessel operations and cargo handling.Marine Industry Applications

Marine Engine Components

Hull Structure Components

Propellers & Propulsion

Deck Equipment & Accessories

Specialized materials and surface treatments designed to withstand harsh marine environments and ensure long-term reliability.

Type II and Type III hard anodizing for aluminum components with enhanced corrosion resistance.

Citric and nitric acid passivation for stainless steel components per ASTM A967 standards.

Specialized marine primers, antifouling coatings, and protective finishes for extended service life.

Stress relief and fatigue resistance enhancement for critical propeller and shaft components.

Our streamlined process ensures efficient project execution from initial design review to final component delivery.

Engineering analysis and DFM optimization for marine applications.

Rapid prototyping and testing for validation before production.

Precision CNC machining and fabrication with quality control.

Comprehensive dimensional and material verification testing.

Secure packaging and logistics coordination for global delivery.

Advanced manufacturing capabilities for complex marine systems and specialized equipment.

Complete propulsion system components including variable pitch propellers, controllable pitch hubs, and transmission components.

Precision machined steering gear components, rudder assemblies, and hydraulic system parts for vessel control systems.

High-precision gears, shafts, and transmission components for marine reduction gearboxes and power transmission systems.

Comprehensive quality management systems and industry certifications ensuring consistent marine-grade quality.

Quality Management System certification for consistent manufacturing processes.

American Bureau of Shipping certification for marine equipment manufacturing.

Special processes certification for critical marine component manufacturing.

American Welding Society certified welding procedures for structural marine applications.

Common questions about our marine CNC manufacturing services and capabilities.

We routinely achieve tolerances as tight as ±0.001″ (±0.025mm) on critical dimensions, with surface finishes down to Ra 0.2μm for propeller blades and engine components. Our 5-axis machining centers and environmental controls ensure consistent precision.

We specialize in marine-grade aluminum alloys (5083, 5086, 6061), stainless steel (316L, 317L, 2205, 2507), bronze alloys, and specialty materials like Inconel, Hastelloy, and titanium. All materials come with full mill certifications and traceability.

Yes, we offer 24/7 emergency machining services for critical vessel repairs. Our rapid response team can prioritize urgent components to minimize vessel downtime, with express shipping available worldwide.

Standard lead times range from 2-4 weeks for most components, depending on complexity and material availability. Rush orders can often be accommodated in 3-7 days for critical applications. Prototypes typically ship within 5-10 business days.

Our horizontal boring mills can accommodate components up to 200″ in length and 80″ in diameter. We specialize in large propeller hubs, shaft machining, and complex 5-axis propeller blade profiling with hydrodynamic optimization.

We provide comprehensive documentation including material certifications, dimensional inspection reports, surface finish verification, NDT test results, and full traceability records. All documentation meets marine industry standards and classification society requirements.

Yes, we provide complete reverse engineering services using 3D scanning and CMM measurement. This is particularly valuable for obsolete marine components where original drawings are unavailable, allowing us to create precise CAD models and manufacturing drawings.

We offer anodizing (Type II/III), passivation per ASTM A967, marine-grade coatings, shot peening for fatigue resistance, and specialized treatments like PTFE coating. All treatments are selected for optimal corrosion resistance in marine environments.