Expert surface treatments including anodizing, electroplating, powder coating, and specialized finishes for aerospace, automotive, medical, and industrial applications

Surface finishing is a critical manufacturing process that modifies the surface properties of materials to enhance their appearance, functionality, and performance. These treatments can improve corrosion resistance, wear resistance, electrical conductivity, and aesthetic appeal.

Our advanced surface finishing capabilities include mechanical, chemical, and electrochemical processes designed to meet the most demanding industry specifications and quality standards.

Comprehensive range of surface treatments to meet diverse industry requirements and enhance part performance

Electrochemical process that creates a durable, corrosion-resistant oxide layer on aluminum surfaces. Available in multiple colors and finishes.

Uses electric current to deposit a thin layer of metal onto the surface, providing enhanced properties and appearance.

Dry finishing process that provides a thick, durable, and uniform coating with excellent color retention and durability.

Chemical treatment that removes free iron and enhances the natural corrosion resistance of stainless steel surfaces.

Chemical conversion coating that provides a black finish while maintaining dimensional accuracy and improving corrosion resistance.

Specialized surface treatments tailored to your specific requirements, including texturing, polishing, and proprietary coatings.

Systematic approach ensuring consistent quality and optimal results for every project

Material analysis and surface preparation requirements assessment

Surface cleaning, degreasing, and pre-treatment processes

Application of selected surface finishing technique with precise control

Comprehensive testing and inspection to ensure specification compliance

Our surface finishing services meet the highest industry standards and regulatory requirements

Quality Management Systems

Aerospace Quality Management

Medical Device Quality Systems

Defense Industry Compliance

Ra 0.025 – 6.3 μm achievable depending on process

Precise control from 0.1 to 100+ μm

ASTM D3359 tape test and pull-off testing

Our surface finishing expertise supports critical applications across diverse industries

Critical components requiring superior corrosion resistance and lightweight properties

Engine components, decorative trim, and functional parts with enhanced durability

Biocompatible finishes for surgical instruments and implantable devices

EMI shielding, conductivity enhancement, and component protection

High-tolerance parts requiring specific surface properties

Manufacturing tools with enhanced wear resistance

Design validation with production-representative finishes

Heavy-duty components in harsh environments

Aesthetic and functional surface enhancements

Mission-critical components with specialized requirements

Comprehensive surface finishing solutions for a wide range of materials and substrates

Industry-leading expertise, quality, and customer service for all your surface treatment needs

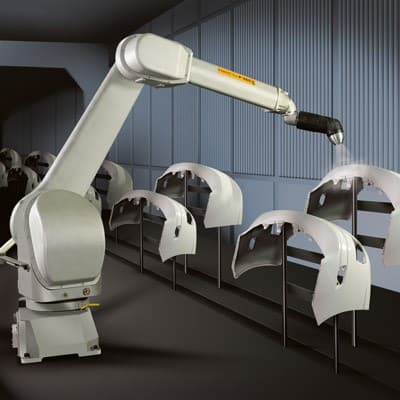

State-of-the-art equipment and proven processes for consistent, high-quality results across all surface finishing applications.

Streamlined processes and efficient workflow management to deliver your finished parts on time, every time.

Experienced engineers and technicians providing technical support and custom solutions for complex requirements.

Rigorous testing and inspection protocols ensuring compliance with industry standards and customer specifications.

Cost-effective solutions without compromising quality, with transparent pricing and no hidden fees.

Dedicated project management and responsive customer service from quote to delivery and beyond.

Modern equipment and automated systems ensuring precision, consistency, and efficiency

Computer-controlled processing for consistent results and optimal efficiency

Climate-controlled facilities with advanced filtration and monitoring systems

In-house testing capabilities for thickness, adhesion, and corrosion resistance

Environmental compliance with advanced waste treatment and recycling

Parts Processed Monthly

Finish Options Available

Coating Precision

Production Capability

Common questions about our surface finishing services and capabilities

We offer a comprehensive range of surface finishing services including anodizing (Type II and Type III), electroplating (nickel, chrome, gold, zinc), powder coating, passivation, black oxide, chemical film (Alodine), electropolishing, and custom specialty finishes. Our capabilities cover both functional and aesthetic treatments for various materials.

We work with a wide range of materials including aluminum alloys (6061, 7075, 2024), stainless steel (300 and 400 series), carbon steel, titanium, brass, copper, and various plastic substrates. Each material has specific finishing options optimized for its properties and intended applications.

We maintain ISO 9001:2015, AS9100D, and ISO 13485 certifications, and are ITAR registered. Our processes comply with industry standards including ASTM, MIL-SPEC, and AMS specifications. We provide full traceability and certification documentation with every order.

Lead times vary by finish type and quantity. Standard finishes like anodizing and powder coating typically require 7-10 business days. Specialized finishes or high-volume orders may require 2-3 weeks. We offer expedited services for urgent requirements and can provide accurate timing during the quoting process.

Yes, we support everything from single prototype parts to high-volume production runs. Our flexible processes and equipment can efficiently handle orders ranging from 1 piece to thousands of parts while maintaining consistent quality throughout.

Absolutely. We can match RAL, Pantone, and custom color specifications for anodizing, powder coating, and painting. We also develop custom finishing solutions for specific performance requirements including specialized coatings for extreme environments or unique aesthetic needs.

For accurate quoting, we need: material specification, part dimensions/drawings, desired finish type and specifications, quantity requirements, and delivery timeline. Photos or samples of existing parts are also helpful for matching finishes or understanding specific requirements.

Yes, our experienced engineers provide Design for Manufacturing (DFM) support to optimize your parts for the selected finishing process. We can recommend the best finish options for your application requirements and help resolve any manufacturing challenges during the design phase.