Professional Busbar Cable Harness Board Manufacturing Services

Integrated power distribution solutions combining advanced busbar technology with precision cable harness assembly for automotive, EV, and industrial applications

What is a Busbar Cable Harness Board?

A busbar cable harness board is an innovative integration of rigid busbar conductors with flexible cable harness systems, providing optimized power distribution and signal transmission in a single, compact assembly solution.

Key Integration Benefits

High Power Distribution

Busbar sections handle high-current applications while cable sections manage control signals and low-voltage connections

Space Optimization

Combines multiple connection types in a single assembly, reducing overall system footprint by up to 60%

Simplified Installation

Pre-assembled integration eliminates multiple connection points and reduces installation time significantly

Enhanced Reliability

Fewer interconnections reduce potential failure points and improve overall system reliability

Advanced Manufacturing Process

Our state-of-the-art manufacturing facility combines precision machining, advanced assembly techniques, and rigorous quality control to produce superior busbar cable harness boards.

Design & Engineering

Custom CAD design using advanced 3D modeling software, electrical simulation, and thermal analysis to optimize performance and ensure manufacturability.

Precision Machining

CNC machining of busbar components from high-grade copper and aluminum materials, ensuring tight tolerances and consistent quality.

Surface Treatment

Application of protective coatings including tin plating, nickel plating, and silver plating to enhance conductivity and corrosion resistance.

Cable Assembly

Professional wire harness assembly using automated crimping, ultrasonic welding, and precise routing according to customer specifications.

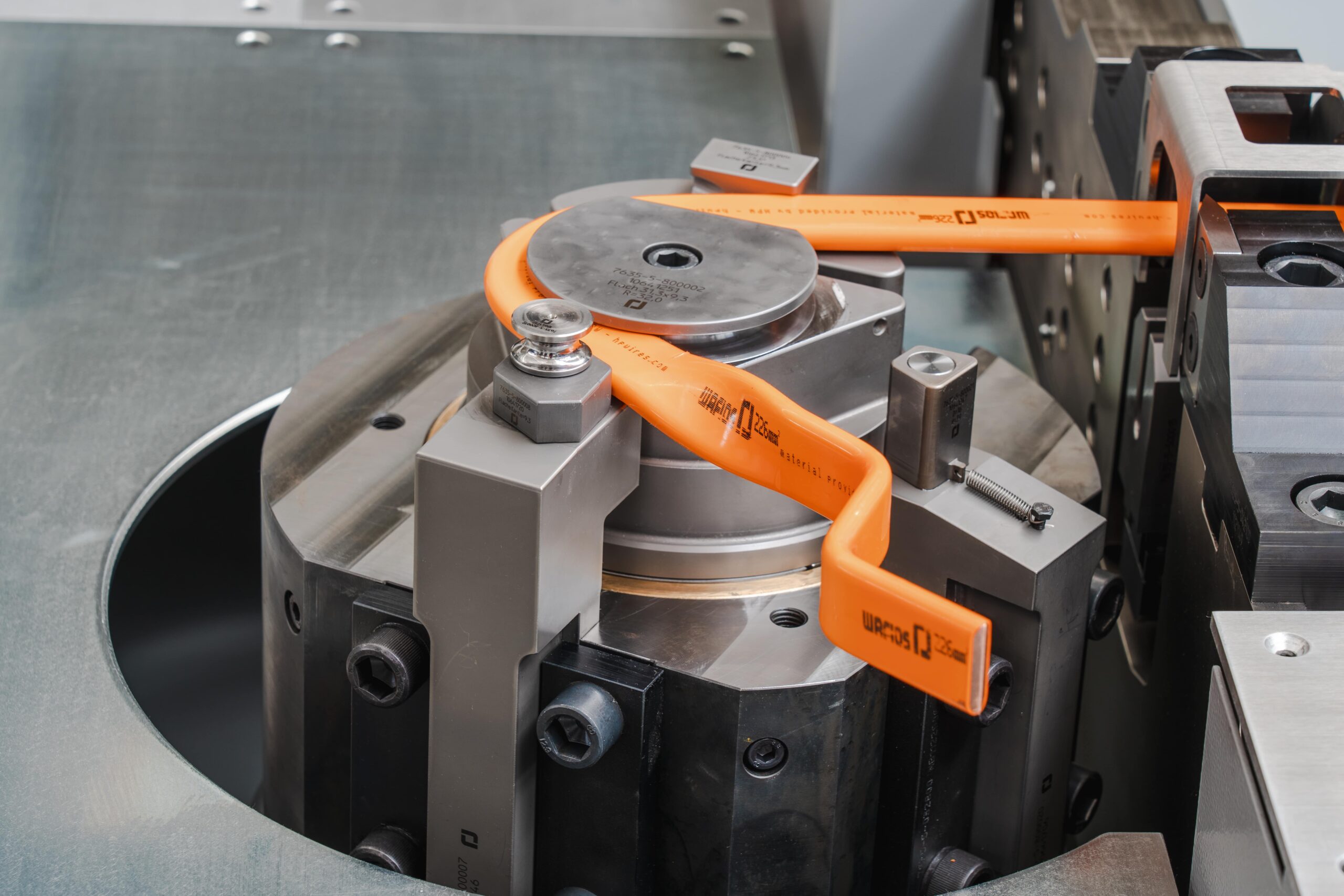

Integration Assembly

Careful integration of busbar and cable components using specialized fixtures and assembly boards to ensure proper alignment and connection integrity.

Quality Testing

Comprehensive electrical testing, continuity verification, insulation resistance testing, and mechanical stress testing to validate performance.

Assembly Board Technology

Our advanced assembly board systems provide the foundation for precise and repeatable manufacturing of complex busbar cable harness boards. These specialized fixtures ensure consistent positioning, proper alignment, and quality control throughout the production process.

Automotive & Electric Vehicle Applications

Our busbar cable harness boards are at the forefront of automotive electrification, providing critical power distribution and control solutions for next-generation vehicles.

EV Power Distribution Systems

Electric vehicles demand sophisticated power management solutions that can handle high voltages and currents while maintaining safety and efficiency. Our integrated busbar cable harness boards provide the perfect solution for these demanding applications.

Battery Management Systems (BMS)

High-voltage busbar sections for main power distribution combined with low-voltage cable harnesses for monitoring and control signals

Motor Controller Integration

Seamless integration between high-power busbars and control cable networks for optimal motor drive performance

Charging Infrastructure

Robust power connections for fast charging systems with integrated communication and safety monitoring

High Voltage DC Systems

Specialized solutions for 400V and 800V EV architectures

Battery Pack Integration

Compact solutions for cell-to-module and module-to-pack connections

Vehicle Harness Integration

Complete vehicle wiring solutions with integrated power distribution

Thermal Management

Advanced cooling system integration for high-performance applications

Technical Specifications & Capabilities

Our manufacturing capabilities span a wide range of specifications to meet diverse application requirements across automotive, industrial, and aerospace sectors.

Busbar Specifications

Continuous current carrying capacity optimized for thermal performance

High-voltage applications including EV and industrial power systems

99.9% pure copper, 6061 aluminum alloy, and specialty brass alloys

Precision tolerance ±0.05mm for critical applications

Tin, nickel, silver plating, and protective coatings

Cable Harness Specifications

Support for both signal and power applications

PVC, XLPE, Teflon, silicone for various temperature ratings

Extended temperature range for automotive and aerospace applications

Molex, TE Connectivity, Delphi, and custom connectors

Custom lengths to meet specific application requirements

Quality Control & Certifications

Our commitment to quality excellence is demonstrated through rigorous testing protocols, comprehensive quality management systems, and internationally recognized certifications.

Comprehensive Testing Protocols

Every busbar cable harness board undergoes extensive testing to ensure reliability, safety, and performance compliance with industry standards.

Electrical Testing

Continuity verification, insulation resistance, dielectric strength, and current carrying capacity validation

Mechanical Testing

Pull strength, bend radius, vibration resistance, and thermal cycling endurance testing

Environmental Testing

Temperature cycling, humidity exposure, salt spray corrosion, and UV resistance testing

Safety Validation

Flammability testing, toxic gas emission, and electrical safety compliance verification

ISO 9001:2015

Quality Management

IATF 16949

Automotive Quality

IPC/WHMA-A-620

Cable Assembly

RoHS Compliant

Environmental

REACH Regulation

Chemical Safety

UL Standards

Fire Safety

Design & Engineering Support

Our experienced engineering team provides comprehensive design support from concept development through production optimization, ensuring your project success.

Concept Development

Initial consultation and feasibility analysis to determine optimal integration of busbar and cable harness components for your specific application.

- • Requirements analysis

- • Preliminary design concepts

- • Cost-benefit evaluation

- • Technical feasibility assessment

3D CAD Design

Advanced 3D modeling using SolidWorks and AutoCAD to create detailed designs with precise dimensions and assembly instructions.

- • Parametric 3D modeling

- • Assembly visualization

- • Drawing generation

- • Design for manufacturability

Simulation & Analysis

Advanced simulation tools for electrical, thermal, and mechanical analysis to optimize performance and validate design integrity.

- • Electrical simulation

- • Thermal analysis

- • Stress analysis

- • EMC/EMI modeling

Prototype Development

Rapid prototyping services to validate design concepts and enable testing before full-scale production commitment.

- • Rapid prototyping

- • Functional testing

- • Design iteration

- • Performance validation

Production Planning

Comprehensive manufacturing process planning including tooling design, assembly fixture development, and quality control procedures.

- • Process flow optimization

- • Tooling design

- • Quality planning

- • Cost optimization

Ongoing Support

Continuous engineering support throughout the product lifecycle including design modifications, process improvements, and technical consultation.

- • Technical consultation

- • Design modifications

- • Process improvements

- • Field support

Industry Applications

Our busbar cable harness boards serve diverse industries where reliable power distribution and signal integrity are critical for operational success.

Automotive & EV

Advanced power distribution solutions for electric and hybrid vehicles, supporting the transition to sustainable transportation.

- • Battery management systems

- • Motor controllers

- • Charging infrastructure

- • Power distribution units

Medical Devices

Precision assemblies for medical equipment requiring the highest levels of reliability and regulatory compliance.

- • Imaging equipment

- • Patient monitoring systems

- • Surgical instruments

- • Diagnostic equipment

Industrial Automation

Robust solutions for industrial control systems, robotics, and manufacturing equipment in demanding environments.

- • Control panels

- • Robotic systems

- • Motor drives

- • Process equipment

Aerospace & Defense

High-reliability assemblies meeting stringent aerospace standards for critical mission applications.

- • Avionics systems

- • Satellite equipment

- • Military vehicles

- • Ground support equipment

Renewable Energy

Power distribution solutions for solar, wind, and energy storage systems supporting the clean energy transition.

- • Solar inverters

- • Wind turbine systems

- • Energy storage

- • Grid tie equipment

Telecommunications

High-performance connectivity solutions for data centers, telecommunications equipment, and network infrastructure.

- • Data center equipment

- • Network switches

- • Telecom infrastructure

- • Server systems

Custom Solutions & Capabilities

We specialize in developing tailored busbar cable harness board solutions that meet unique requirements and challenging specifications.

Why Choose Our Custom Solutions?

Rapid Development

Fast turnaround from concept to prototype, typically 2-4 weeks for initial samples

Expert Engineering

Dedicated team of engineers with 15+ years of experience in busbar and harness design

Scalable Production

From prototype quantities to high-volume production with consistent quality

Cost Optimization

Value engineering to reduce costs while maintaining performance and quality standards

Global Support

Worldwide manufacturing and support capabilities with local engineering support

Custom Design Process

Initial Consultation

Requirements gathering and technical discussion

Design Development

3D modeling, simulation, and optimization

Prototype Manufacturing

Rapid prototyping and initial testing

Validation & Testing

Comprehensive testing and performance validation

Production Launch

Full-scale manufacturing and quality assurance

Frequently Asked Questions

Find answers to common questions about our busbar cable harness board manufacturing services and capabilities.

Busbar cable harness boards offer several key advantages: 1) Space efficiency - up to 60% reduction in installation space compared to traditional cable systems, 2) Improved reliability - fewer connection points reduce potential failure modes, 3) Enhanced current carrying capacity - busbars can handle higher currents with lower resistance, 4) Simplified installation - integrated design reduces assembly time and complexity, 5) Better thermal management - superior heat dissipation compared to bundled cables, and 6) Cost effectiveness - reduced material costs and installation labor.

Our busbar cable harness boards can accommodate a wide range of electrical specifications: Current ratings from 50A to 6000A continuous, voltage ratings up to 1000V DC (higher voltages available for special applications), and power handling capabilities exceeding 1MW for high-performance applications. The specific ratings depend on factors such as conductor material, cross-sectional area, thermal management, and environmental conditions. We work closely with customers to optimize designs for their specific electrical requirements.

For busbars, we primarily use 99.9% pure electrolytic copper (C101) for optimal conductivity, 6061-T6 aluminum alloy for weight-sensitive applications, and specialty brass alloys for specific environmental requirements. Surface treatments include tin plating (most common), nickel plating for harsh environments, and silver plating for high-frequency applications. For cable components, we use high-grade copper conductors with various insulation materials including PVC, XLPE, Teflon, and silicone, selected based on temperature requirements, flexibility needs, and environmental conditions.

We maintain comprehensive quality certifications including ISO 9001:2015 for quality management systems, IATF 16949 for automotive industry requirements, and IPC/WHMA-A-620 for cable and wire harness assemblies. Our products comply with RoHS directives for environmental safety, REACH regulations for chemical compliance, and various UL standards for electrical safety. For automotive applications, we meet specific OEM requirements and standards such as VDA, USCAR, and individual manufacturer specifications. All products undergo rigorous testing including electrical performance, mechanical stress, environmental exposure, and safety validation.

Lead times vary based on complexity and quantity: Initial design and engineering typically takes 1-2 weeks, prototype development requires 2-4 weeks depending on complexity, tooling development (if required) takes 3-6 weeks, and production quantities range from 2-8 weeks based on volume and specifications. For urgent projects, we offer expedited services with reduced lead times. We work closely with customers to establish realistic timelines and provide regular progress updates throughout the development and manufacturing process.

Yes, we provide comprehensive engineering support throughout the entire project lifecycle. Our services include initial concept development and feasibility analysis, 3D CAD design using SolidWorks and AutoCAD, electrical and thermal simulation using advanced software tools, mechanical stress analysis and optimization, design for manufacturability (DFM) recommendations, prototype development and testing support, and ongoing technical consultation during production. Our experienced engineering team has over 15 years of combined experience in busbar and cable harness design, ensuring optimal solutions for your specific requirements.

Every busbar cable harness board undergoes comprehensive testing including electrical performance verification (continuity, insulation resistance, dielectric strength), current carrying capacity validation under thermal stress, mechanical testing (pull strength, bend radius, vibration resistance), environmental testing (temperature cycling, humidity exposure, corrosion resistance), and safety compliance verification (flammability, electrical safety). We also perform application-specific testing such as EMC/EMI compliance for automotive applications, salt spray testing for marine environments, and extended life cycle testing for critical applications. All testing is documented and traceable, with certificates provided to customers.

Absolutely. We are equipped to handle projects ranging from single prototypes to high-volume production runs exceeding 100,000 units annually. For prototypes and low volumes, we use flexible manufacturing processes and quick-turn capabilities. For high-volume production, we implement automated assembly lines, dedicated tooling, and statistical process control to ensure consistent quality and cost efficiency. Our scalable manufacturing approach allows us to grow with your project from initial development through full production, maintaining quality and cost competitiveness at every volume level.

Ready to Start Your Project?

Get instant pricing and design feedback for your complex components. Our engineering team is ready to help you leverage the full potential of CNC machining.

Address

No. 225, Delong Street, Chang'an Town, Dongguan City, Guangdong Province

connect

email: info@topcncpro.com

Phone: +86 15145145178

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.