Professional Aluminum Heat Sink Manufacturing Services

Leading manufacturer of lightweight, cost-effective aluminum heat sinks with superior thermal management solutions for electronics, automotive, and LED applications.

67% Lighter

Than copper alternatives

70% Cost Savings

Compared to copper heat sinks

167 W/mK

Excellent thermal conductivity

Superior Corrosion

Resistance with anodizing

Why Choose Aluminum Heat Sinks?

Aluminum heat sinks offer the perfect balance of thermal performance, weight efficiency, and cost-effectiveness for modern thermal management applications.

Lightweight Design

Aluminum is approximately 3 times lighter than steel and 67% lighter than copper, reducing overall system weight while maintaining excellent thermal performance. Ideal for aerospace, automotive, and portable electronics applications.

Cost-Effective Solution

Aluminum costs approximately one-third the price of copper while delivering 60% of its thermal conductivity. This exceptional cost-to-performance ratio makes aluminum the preferred choice for high-volume production.

Easy Manufacturing

Aluminum's excellent machinability and extrusion properties enable complex geometries, tight tolerances, and efficient mass production. Lower melting point reduces energy costs during manufacturing.

Corrosion Resistance

Natural oxide layer provides inherent corrosion resistance. Anodizing treatment further enhances durability and can improve thermal performance by up to 33% through increased surface emissivity.

Advanced Aluminum Extrusion Process

Our state-of-the-art extrusion manufacturing process delivers precision aluminum heat sinks with optimal thermal performance and dimensional accuracy.

Precision Extrusion Technology

Billet Preparation

High-grade 6061/6063 aluminum billets are heated to optimal extrusion temperature of 450-500°C for maximum formability and grain structure control.

Die Design & Manufacturing

Precision steel dies engineered for complex fin geometries, optimal material flow, and dimensional consistency. Custom dies available for unique thermal requirements.

Extrusion Process

High-pressure hydraulic rams force heated aluminum through precision dies, creating continuous profiles with excellent surface finish and dimensional accuracy ±0.1mm.

Secondary Operations

CNC machining, cutting to length, drilling, and finishing operations ensure perfect fit and optimal thermal interface preparation.

Process Specifications

Extrusion Temp

450-500°C

Tolerance

±0.1mm

Max Length

12 meters

Surface Finish

Ra 1.6μm

Premium Aluminum Alloys: 6061 vs 6063

We utilize the finest 6000 series aluminum alloys, each optimized for specific thermal management applications and manufacturing requirements.

6061 Aluminum Alloy

Ideal Applications:

- High-stress thermal applications

- Automotive heat exchangers

- Aerospace thermal management

- Heavy-duty industrial equipment

6063 Aluminum Alloy

Ideal Applications:

- Complex extruded profiles

- LED lighting heat sinks

- Electronics cooling solutions

- Decorative anodized finishes

Material Selection Guide

Choose 6061 When:

- Higher mechanical strength required

- Structural integrity is critical

- Aerospace or automotive applications

- High-stress thermal cycling

Choose 6063 When:

- Complex extrusion shapes needed

- Superior surface finish required

- Anodizing quality is important

- Cost optimization is priority

Advanced Anodizing Surface Treatment

Professional anodizing processes enhance thermal performance, corrosion resistance, and aesthetic appeal while providing electrical isolation and improved durability.

Anodizing Benefits & Process

Enhanced Thermal Performance

Black anodized surfaces increase thermal radiation by up to 33%, improving overall heat dissipation efficiency through enhanced emissivity (ε ≈ 0.9 vs 0.1 for raw aluminum).

Superior Corrosion Protection

Anodic oxide layer (5-25μm thick) provides excellent protection against atmospheric corrosion, salt spray, and chemical exposure, extending service life significantly.

Electrical Isolation

Anodized layer provides electrical insulation (breakdown voltage >1000V), preventing short circuits and improving safety in electronic applications.

Black Anodized

Maximum thermal radiation, premium appearance, excellent for high-performance applications

Thickness: 10-25μm

Clear Anodized

Natural aluminum appearance, corrosion protection, cost-effective solution for general applications

Thickness: 5-15μm

Color Anodized

Custom colors available, branding opportunities, enhanced aesthetics for consumer products

Thickness: 10-20μm

Diverse Applications Across Industries

Our aluminum heat sinks serve critical thermal management roles across automotive, electronics, LED lighting, and industrial applications.

LED Lighting Systems

High-power LED arrays require efficient thermal management to maintain optimal performance and lifespan. Our aluminum heat sinks provide excellent heat dissipation for:

- • Street lighting and outdoor fixtures

- • Industrial and warehouse lighting

- • Automotive LED headlights

- • Stage and architectural lighting

- • High-bay and flood lighting

Electronics & Computing

Modern electronics generate significant heat that must be managed effectively. Our solutions serve:

- • CPU and GPU cooling systems

- • Power supply modules

- • Telecommunications equipment

- • Server and data center hardware

- • Power amplifiers and RF systems

Automotive Systems

Automotive electronics operate in challenging environments requiring robust thermal solutions:

- • Engine control units (ECUs)

- • Electric vehicle battery management

- • Power inverters and converters

- • LED headlight assemblies

- • Transmission control modules

Industrial Applications

Power Electronics

Variable frequency drives, welding equipment, motor controllers, and industrial power supplies.

Renewable Energy

Solar inverters, wind turbine controllers, and energy storage system thermal management.

Telecommunications

5G base stations, network equipment, satellite communication systems, and RF amplifiers.

Technical Specifications & Capabilities

Comprehensive technical data and manufacturing capabilities for aluminum heat sink design and production.

Material Properties

| Property | 6061-T6 | 6063-T6 | Unit |

|---|---|---|---|

| Thermal Conductivity | 167 | 200 | W/mK |

| Density | 2.70 | 2.69 | g/cm³ |

| Tensile Strength | 240 | 186 | MPa |

| Yield Strength | 180 | 145 | MPa |

| Specific Heat | 0.90 | 0.90 | J/g°C |

| Coefficient of Expansion | 23.6 | 23.4 | ×10⁻⁶/°C |

Manufacturing Capabilities

Maximum Length

12 meters

Tolerance

±0.1mm

Surface Finish

Ra 1.6μm

Min Wall Thickness

1.0mm

Annual Capacity

10M pieces

Lead Time

2-4 weeks

Available Processes:

Quality Standards & Certifications

ISO 9001:2015

Quality Management

TS 16949

Automotive Quality

RoHS Compliant

Environmental

UL Recognized

Safety Standards

Featured Product Gallery

Explore our diverse range of aluminum heat sink solutions, from standard profiles to custom-engineered thermal management systems.

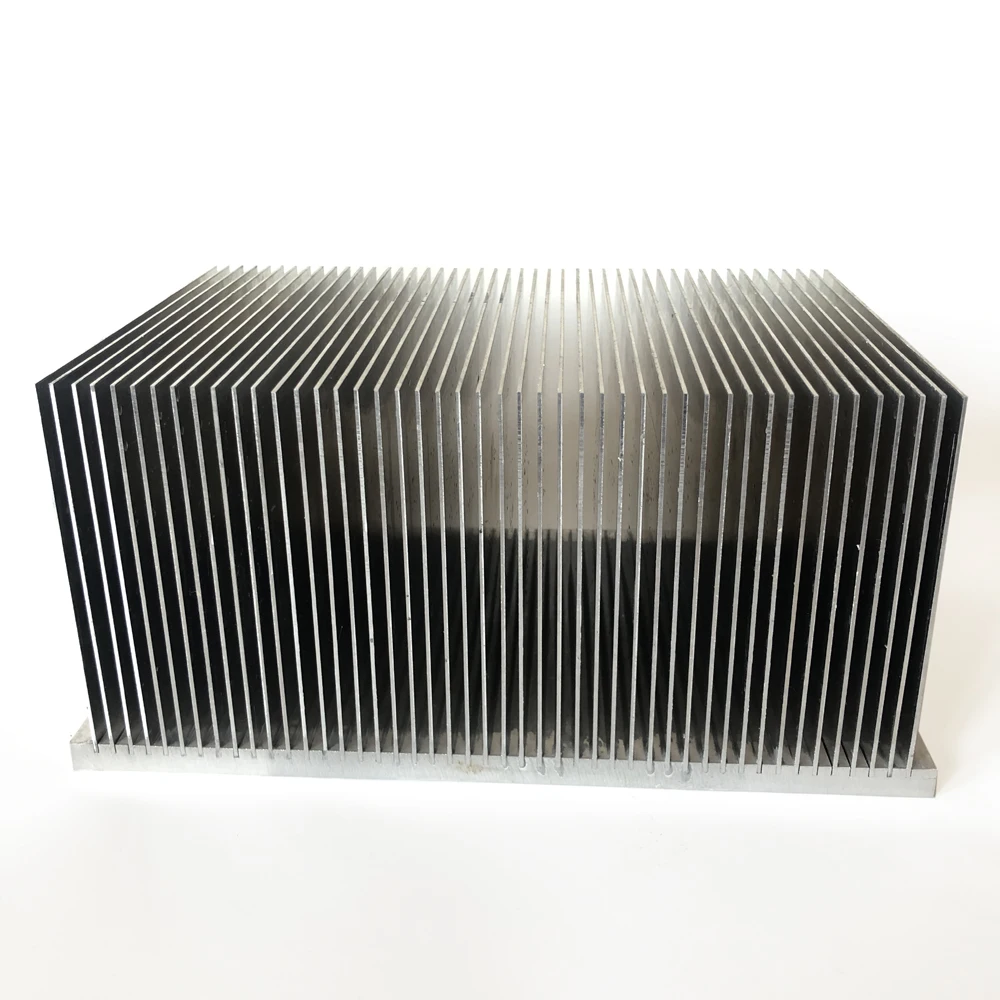

Straight Fin Heat Sinks

Standard extruded profiles with optimized fin spacing for general cooling applications.

CNC Machined Heat Sinks

Precision machined aluminum heat sinks with custom mounting features and optimized geometry.

Custom Profile Heat Sinks

Application-specific designs with optimized thermal paths and integrated mounting solutions.

LED Heat Sinks

Specialized thermal solutions for high-power LED applications with optimized radiation fins.

Electronics Heat Sinks

Compact cooling solutions for semiconductor devices, amplifiers, and power electronics.

Large Format Heat Sinks

High-capacity thermal management solutions for industrial and power applications.

Frequently Asked Questions

Expert answers to common questions about aluminum heat sink design, manufacturing, and applications.

Why choose aluminum over copper for heat sinks?

Aluminum offers several key advantages: it's 67% lighter than copper, costs approximately 70% less, and provides excellent thermal conductivity (167 W/mK for 6061). While copper has higher thermal conductivity (388 W/mK), aluminum's superior cost-to-performance ratio, corrosion resistance, and ease of manufacturing make it ideal for most applications. The weight savings are particularly important in automotive and aerospace applications.

What's the difference between 6061 and 6063 aluminum alloys?

6061 aluminum offers higher strength (240 MPa tensile vs 186 MPa for 6063) and better structural integrity, making it ideal for high-stress applications. 6063 has better thermal conductivity (200 W/mK vs 167 W/mK), superior extrudability for complex shapes, and better surface finish quality. Choose 6061 for structural applications and 6063 for complex extrusions and optimal thermal performance.

How does anodizing improve heat sink performance?

Anodizing, especially black anodizing, significantly improves thermal radiation by increasing surface emissivity from 0.1 (raw aluminum) to 0.9 (black anodized). This can improve overall cooling performance by up to 33%. Additionally, anodizing provides corrosion protection, electrical isolation (>1000V breakdown), and enhanced durability. The oxide layer (5-25μm thick) also improves wear resistance and surface hardness.

What design considerations are important for aluminum heat sinks?

Key design factors include: fin geometry (height, thickness, spacing) optimized for airflow conditions, base thickness for heat spreading, mounting interface design, and material selection. Consider thermal cycling effects, coefficient of expansion matching with components, and manufacturing constraints. Fin spacing should match airflow velocity - closer fins for higher airflow, wider spacing for natural convection.

What are the minimum order quantities and lead times?

MOQ varies by product complexity: standard profiles start at 100 pieces, custom extrusions typically require 500-1000 pieces minimum. Lead times are 2-4 weeks for standard products and 4-8 weeks for custom designs including tooling. Prototype quantities (5-50 pieces) can be machined from stock profiles with 1-2 week delivery. Rush orders available with premium pricing.

Can you provide thermal analysis and design optimization?

Yes, we offer comprehensive thermal analysis using CFD modeling and FEA simulation. Our engineering team can optimize fin geometry, base thickness, and mounting configurations based on your specific power dissipation, airflow, and space constraints. We also provide thermal testing services and performance validation to ensure optimal cooling efficiency.

What quality standards and certifications do you maintain?

We maintain ISO 9001:2015 quality management certification, TS 16949 for automotive applications, and UL recognition for safety standards. All products are RoHS compliant and undergo comprehensive quality control including dimensional inspection, surface quality assessment, and thermal performance validation. Material certifications and test reports are provided with each shipment.

How do aluminum heat sinks perform in harsh environments?

Aluminum heat sinks excel in harsh environments when properly treated. Anodized aluminum provides excellent corrosion resistance against salt spray, chemicals, and UV exposure. Operating temperature range is -40°C to +150°C for most alloys. For extreme environments, we offer specialized coatings and sealed designs. Aluminum's natural oxide layer provides inherent protection against atmospheric corrosion.

What secondary operations and finishing options are available?

We offer comprehensive secondary operations including CNC machining, drilling, tapping, cutting to length, and assembly. Finishing options include clear, black, or colored anodizing, powder coating, chemical etching, and polishing. We can also provide thermal interface material application, mounting hardware installation, and custom packaging services.

How do you ensure consistent thermal performance across production batches?

We maintain strict process controls including alloy composition verification, extrusion temperature monitoring, and dimensional inspection. Each batch undergoes thermal conductivity testing and surface finish verification. Statistical process control ensures consistent fin geometry and surface area. Our quality management system tracks performance data across all production batches to maintain consistent thermal performance.

Can aluminum heat sinks be recycled at end of life?

Yes, aluminum is 100% recyclable without loss of properties. Recycling aluminum requires only 5% of the energy needed for primary production, making it highly sustainable. Even anodized aluminum can be recycled after de-coating. We support circular economy principles and can provide guidance on end-of-life recycling programs for your products.

What technical support do you provide during product development?

Our engineering team provides comprehensive support including thermal modeling, design optimization, material selection guidance, and prototyping services. We offer design for manufacturability reviews, cost optimization analysis, and performance validation testing. Technical documentation, 3D CAD models, and thermal simulation reports are provided throughout the development process.