Precision CNC machining, rapid prototyping, and custom components for solar, wind, battery storage, hydrogen, and clean energy systems. Accelerating the global transition to sustainable energy.

Delivering precision manufacturing solutions that accelerate renewable energy deployment with unmatched quality and speed.

Reduce development cycles by up to 50% with our rapid prototyping and manufacturing capabilities for renewable energy components.

Achieve tolerances as tight as ±0.001″ with our advanced CNC machining capabilities designed for renewable energy applications.

ISO 9001:2015 certified manufacturing with comprehensive quality control for mission-critical energy infrastructure.

Comprehensive manufacturing solutions for every aspect of renewable energy production

5-axis CNC machining centers capable of handling parts up to 3000mm for large solar mounting systems

Specialized tooling for renewable energy materials including aluminum alloys, stainless steel, and composites

Environmental testing and validation for outdoor energy applications

Surface finish capabilities from Ra 0.8μm to 3.2μm depending on application requirements

Advanced additive manufacturing for complex geometries and rapid design validation

Precision forming and welding for enclosures and structural components

Complete assembly and testing solutions for renewable energy systems

Specialized manufacturing solutions across the entire renewable energy ecosystem

Precision manufacturing for photovoltaic mounting systems, tracking components, and solar infrastructure with exceptional durability and performance.

Extruded aluminum profiles with precision end caps

High-precision drive systems and bearings

Weather-resistant enclosures with thermal management

Corrosion-resistant electrical connections

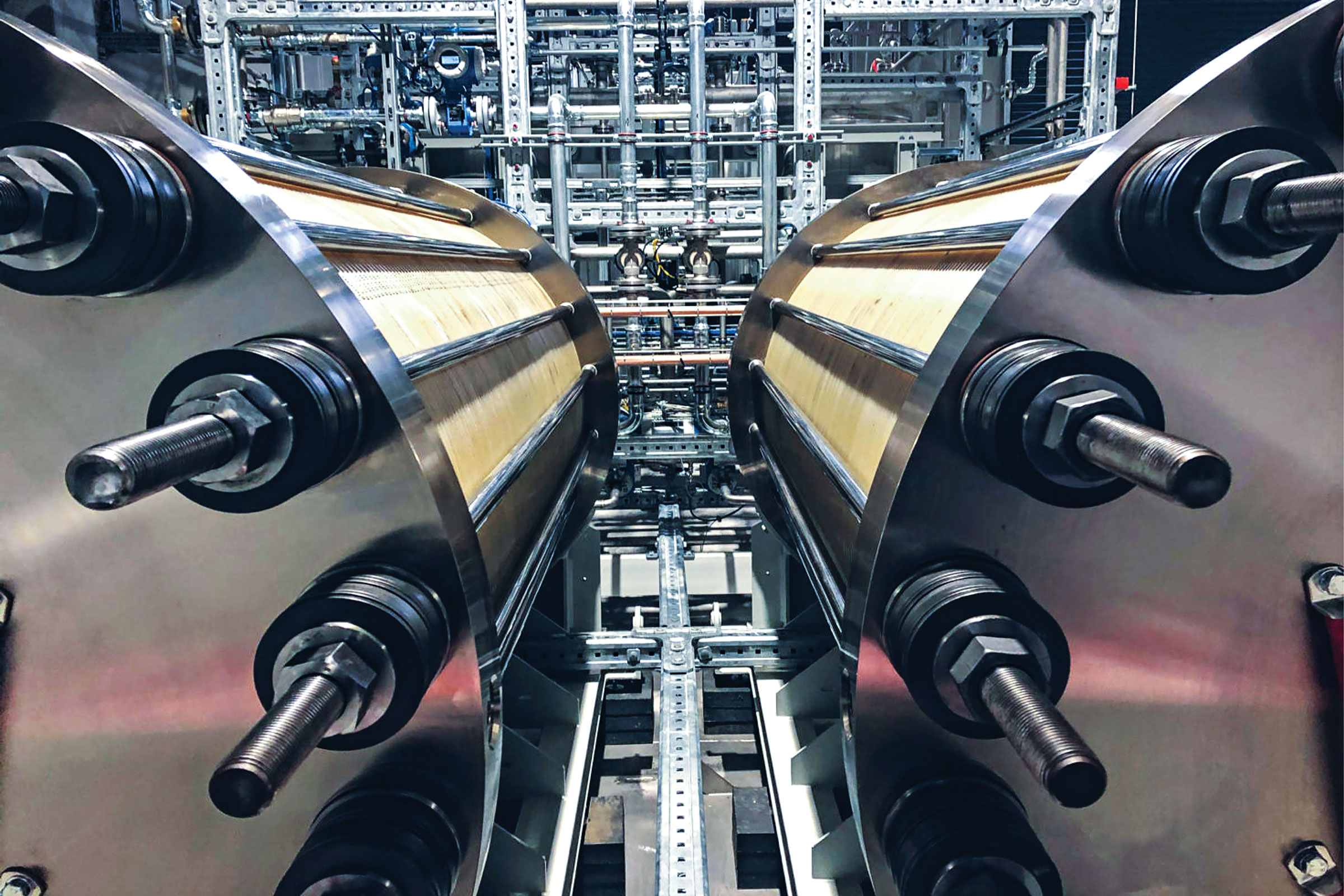

Large-scale manufacturing capabilities for wind turbine components, from precision gearbox parts to massive tower sections and blade components.

High-precision gear systems and bearing assemblies

Root sections and structural reinforcements

Welded steel structures with precision flanges

Structural housings for generator systems

Specialized manufacturing for BESS components including thermal management systems, structural enclosures, and safety systems for grid-scale energy storage.

Fire-rated containers with ventilation systems

Precision heat exchangers and thermal interfaces

Modular battery mounting and connection systems

Fire suppression and monitoring equipment

Precision manufacturing for electrolyzer components, hydrogen storage systems, and fuel cell infrastructure supporting the hydrogen economy.

High-precision electrode assemblies and membranes

High-pressure hydrogen storage tanks

Thermal management for electrolysis processes

Process monitoring and safety equipment

Manufacturing precision components for electric vehicle charging stations, from housing fabrication to power delivery systems and user interfaces.

Weather-resistant housings with cable management

Heat sinks and thermal management components

User interface and screen mounting systems

Emergency shut-off and protection devices

Our proven development process ensures your renewable energy components meet the highest standards

DFM optimization and manufacturability assessment

Fast iteration with 3D printing and CNC prototypes

Environmental testing and performance validation

Tooling design and manufacturing process optimization

Full-scale manufacturing with quality assurance

Specialized materials and finishes optimized for renewable energy environments

6061-T6, 5052-H32 for structural components and solar mounting systems

304/316L for corrosion resistance in marine and industrial environments

PEEK, POM, and glass-filled nylon for electrical insulation

Carbon fiber and fiberglass for lightweight structural applications

Type II and III anodizing for enhanced corrosion resistance

Weather-resistant finishes with UV stability for outdoor applications

Stainless steel passivation for maximum corrosion protection

Zinc, nickel, and specialized coatings for electrical components

Meeting the highest standards for renewable energy manufacturing

Quality management systems certification

Aerospace quality management standard

Restriction of hazardous substances

Safety certification for electrical components

Get answers to common questions about renewable energy manufacturing

We achieve tolerances as tight as ±0.001″ (±0.025mm) for critical components. Our CNC machining capabilities include dimensional tolerances of 0.01mm, geometric tolerances of 0.01mm, and surface roughness as low as Ra 0.2μm for precision applications in solar tracking systems and wind turbine components.

All our renewable energy components undergo rigorous environmental testing including salt spray testing to ASTM B117 standards, UV exposure testing, thermal cycling, and mechanical load testing to simulate wind and snow loading conditions. We use specialized materials and surface treatments designed for 25+ year service life in outdoor installations.

Our rapid prototyping services deliver initial prototypes in 3-5 business days for simple components and 1-2 weeks for complex assemblies. We offer expedited services for urgent projects and can provide same-day quotes with detailed DFM feedback to accelerate your development timeline.

Yes, we have extensive experience with utility-scale renewable energy projects. Our production capabilities include large-format CNC machining for components up to 3000mm in length, high-volume injection molding, and automated assembly lines. We can scale from prototype quantities to millions of parts annually while maintaining consistent quality.

We maintain ISO 9001:2015 quality management certification, AS9100D aerospace standard, and work with UL listed components. Our facilities are audited regularly, and we provide comprehensive documentation including material certifications, dimensional reports, and traceability records required for renewable energy applications.

Absolutely. Our engineering team specializes in Design for Manufacturing (DFM) optimization for renewable energy components. We provide recommendations for material selection, structural optimization, cost reduction, and manufacturability improvements while ensuring compliance with industry standards and environmental requirements.