Advanced CNC machining solutions for critical railway infrastructure components including wheels, axles, brake systems, track components, switch points, and coupling systems. Delivering unmatched precision and reliability for the global rail industry.

With decades of experience in precision CNC manufacturing, we specialize in producing critical railway and locomotive components that meet the most stringent safety and performance standards. Our state-of-the-art facilities and advanced machining technologies ensure every component delivers exceptional reliability for rail operations worldwide.

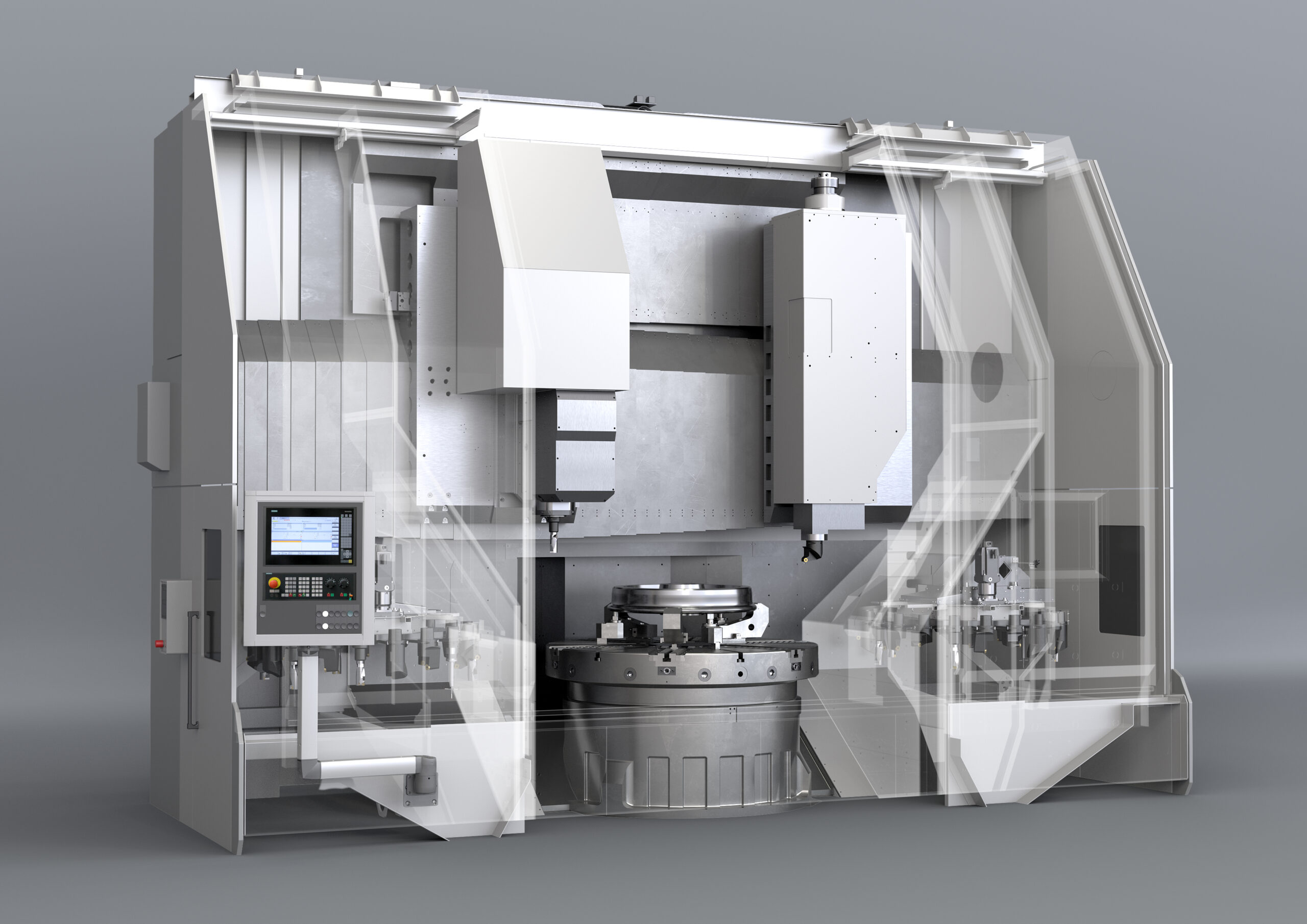

Multi-axis CNC machining centers with precision capabilities for complex geometries and tight tolerances

Comprehensive quality control systems ensuring compliance with international railway standards

Efficient production processes and project management for on-time delivery of critical components

Specialized CNC machining and manufacturing solutions for all critical railway infrastructure components

Precision manufacturing of railway wheels and axles using advanced CNC turning and milling technologies. Our capabilities include complete wheelset manufacturing, axle machining, and wheel reprofiling services for passenger trains, freight locomotives, and high-speed rail systems.

Technical Specifications: Diameter tolerance ±0.01mm, Surface roughness Ra0.2μm, Dimensional accuracy to railway industry standards

Critical safety component manufacturing for railway brake systems including brake discs, brake pads, brake cylinders, and pneumatic system components. Our precision machining ensures optimal braking performance and safety compliance for all types of rolling stock.

Safety Standards: All brake components manufactured to AAR, EN, and UIC standards with comprehensive testing and certification

Precision manufacturing of railway track infrastructure components including rail joints, switch points, crossings, and turnout systems. Our advanced machining capabilities ensure perfect geometric accuracy and durability for heavy-duty rail operations.

Precision Engineering: Geometric tolerances ±0.02mm, surface finish requirements for optimal wheel-rail interface

Comprehensive manufacturing of railway coupling systems including automatic couplers, draft gears, and connection hardware. Our precision machining ensures reliable mechanical, pneumatic, and electrical connections between railway vehicles.

Connection Reliability: Designed for millions of coupling cycles with enhanced durability and maintenance-free operation

State-of-the-art CNC machining technologies and processes for railway component production

5-axis CNC milling and turning centers capable of handling complex geometries and large components up to 10 meters in length

Surface and cylindrical grinding capabilities for achieving mirror finishes and tolerances down to ±0.005mm

In-house heat treatment facilities for stress relief, hardening, and tempering to meet railway material specifications

CMM inspection, non-destructive testing, and material certification to ensure compliance with international standards

From design to delivery, our systematic approach ensures quality and precision at every step

Technical analysis, CAD modeling, and manufacturing planning based on customer specifications and railway standards

Sourcing of certified railway-grade materials with full traceability and material certification documentation

Advanced CNC machining, turning, and grinding operations using state-of-the-art equipment and tooling

Comprehensive inspection, testing, and certification to ensure compliance with international railway standards

Industry-leading expertise, advanced technology, and commitment to railway safety and performance

Over 30 years of specialized experience in railway component manufacturing with deep understanding of industry requirements and safety standards

Certified to international railway standards including AAR, EN, UIC, and AREMA with comprehensive quality management systems

State-of-the-art CNC machining centers, automated quality control systems, and digital manufacturing processes for superior precision

Collaborative engineering support, custom design capabilities, and long-term partnerships with railway operators and OEMs worldwide

Common questions about our railway component manufacturing services

We manufacture railway components to all major international standards including AAR (Association of American Railroads), EN European Norms, UIC (International Union of Railways), AREMA (American Railway Engineering and Maintenance-of-Way Association), and various national railway standards. Our quality management system is ISO 9001:2015 certified, ensuring consistent quality and traceability throughout the manufacturing process.

Lead times vary depending on component complexity and order quantity. Standard components typically require 4-8 weeks for production, while custom-engineered parts may take 8-12 weeks. For urgent requirements, we offer expedited services. Large locomotive wheels and axles may require 10-16 weeks due to material sourcing and extensive machining requirements. We provide detailed project timelines during the quotation process.

Yes, we accommodate everything from single prototype components to high-volume production runs. Our flexible manufacturing capabilities allow us to efficiently handle prototype development for new railway systems, low-volume specialty components, maintenance and repair parts, as well as large-scale production orders. We work closely with railway OEMs, operators, and maintenance facilities to meet their specific volume requirements.

Our comprehensive quality control includes incoming material inspection with certified test reports, in-process inspection at every machining stage, final dimensional inspection using CMM equipment, surface finish verification, non-destructive testing (NDT) when required, material traceability documentation, and final certification packages. All components undergo rigorous testing to ensure they meet or exceed specified tolerances and performance requirements.

Absolutely. Our experienced engineering team provides comprehensive design support including design for manufacturability (DFM) analysis, material selection guidance, cost optimization recommendations, custom component design, reverse engineering services, and technical consultation for railway applications. We work as a true partner to help optimize your railway component designs for performance, reliability, and cost-effectiveness.

We machine a wide range of railway-approved materials including high-strength carbon steels (such as AISI 1045, 4140), alloy steels for heavy-duty applications, stainless steels for corrosion resistance, cast iron and ductile iron for brake components, aluminum alloys for lightweight applications, and specialty railway grades. All materials come with certified mill test certificates and full traceability documentation as required by railway standards.